Automatic hardness testing machines play a crucial role in various industries where hardness testing of materials is essential. These machines provide accurate and reliable measurements, making them an indispensable tool for quality control and product development. In this article, we will explore the significance of automatic hardness testing machines and their applications in different sectors.

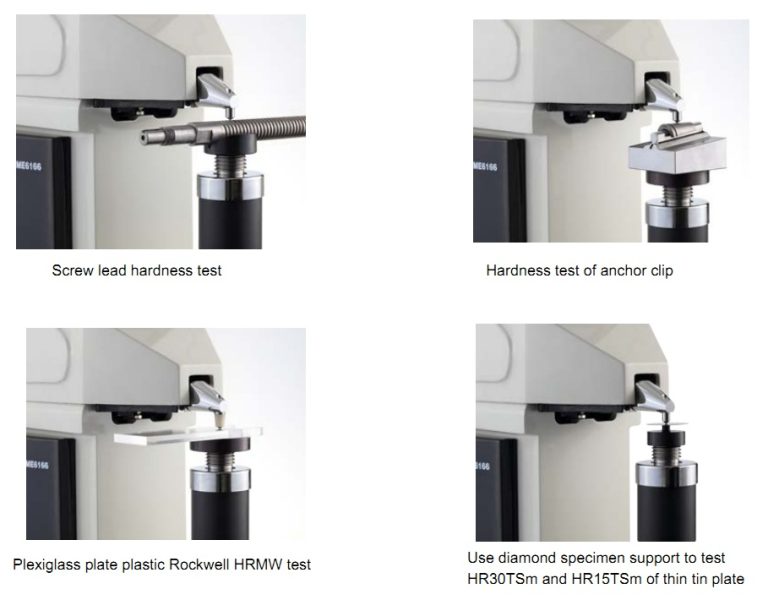

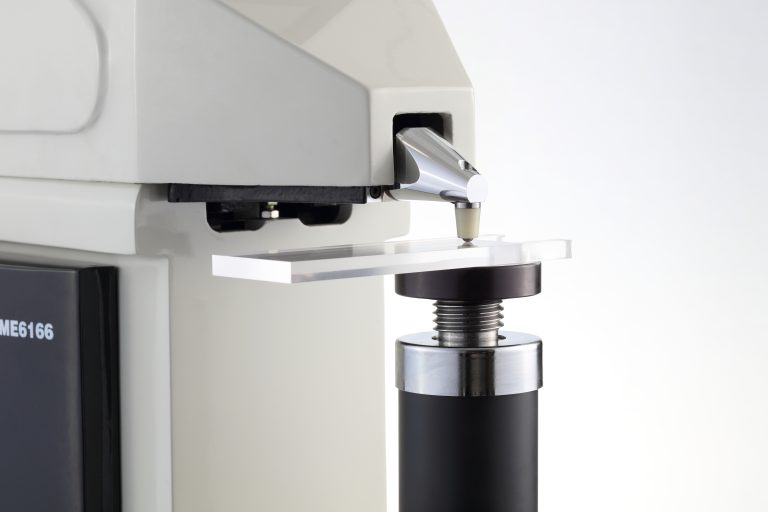

Firstly, let’s understand what automatic hardness testing machines are. These machines are designed to measure the hardness of a material, which refers to its resistance to indentation or penetration. Hardness testing is vital in determining the mechanical properties and durability of materials. It helps ensure that the material meets the required specifications and performs well under different conditions.

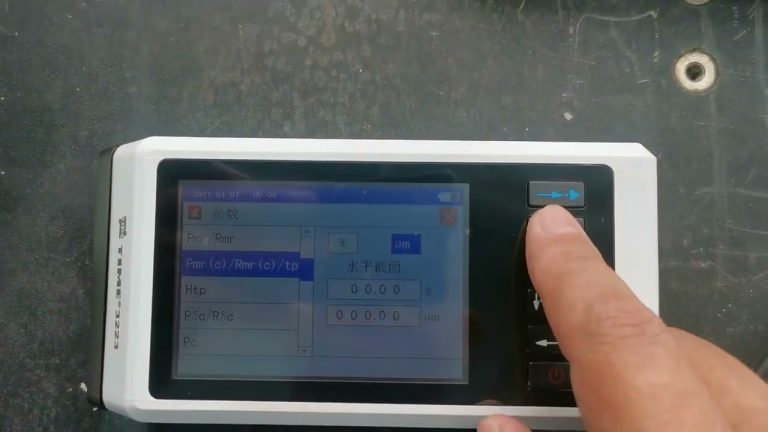

One of the key advantages of automatic hardness testing machines is their ability to provide precise and repeatable results. These machines use advanced technology, such as load cells and electronic sensors, to measure the depth or size of the indentation made by an indenter on the material’s surface. The data collected is then analyzed and converted into a hardness value. This automated process eliminates human error and ensures consistent and accurate measurements.

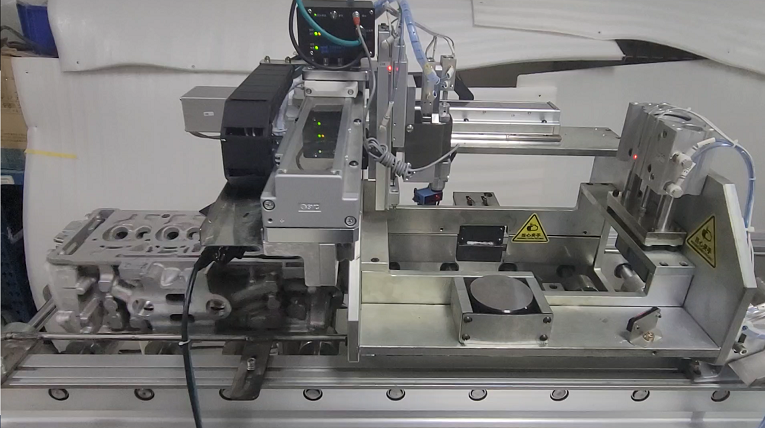

Automatic hardness testing machines are widely used in industries such as automotive, aerospace, manufacturing, and research laboratories. In the automotive industry, these machines are used to test the hardness of engine components, gears, and other parts to ensure their reliability and longevity. In the aerospace industry, the hardness of materials used in aircraft structures and components is crucial for safety and performance. Manufacturers rely on automatic hardness testing machines to verify the quality of their products and meet industry standards.

Moreover, automatic hardness testing machines are essential in research and development activities. Scientists and engineers use these machines to study the behavior of different materials under various conditions. They can evaluate the effect of heat treatment, surface coatings, or alloy compositions on the hardness of materials. This information is crucial for optimizing material selection, improving product design, and enhancing overall performance.

In addition to their accuracy and reliability, automatic hardness testing machines offer other advantages. They are quick and efficient, allowing for high-volume testing in a short period. These machines can also measure the hardness of multiple points on a material, providing a comprehensive hardness profile. Furthermore, they offer non-destructive testing, allowing the material to remain intact after the test, which is especially important for expensive or limited samples.

Automatic hardness testing machines are of utmost importance in various industries and research fields. Their ability to provide precise, repeatable, and non-destructive measurements plays a vital role in quality control, product development, and research activities. These machines ensure that materials meet the required specifications, perform well under different conditions, and contribute to the overall success and safety of products.