When it comes to testing the hardness of materials, a hardness tester is an essential tool. It helps in determining the strength, durability, and quality of various materials. However, with a wide range of hardness testers available in the market, it can be challenging to choose the right one. This article will guide you on how to select a suitable hardness tester based on your requirements.

1. Determine the Testing Method:

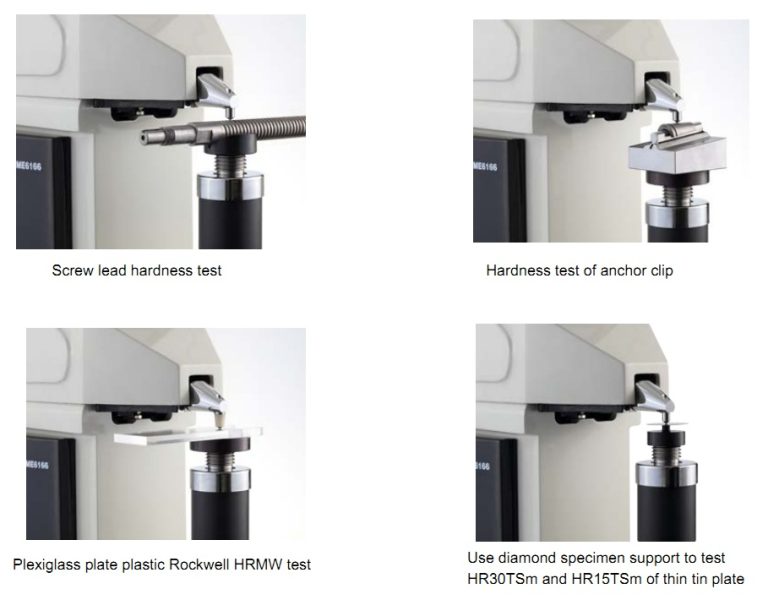

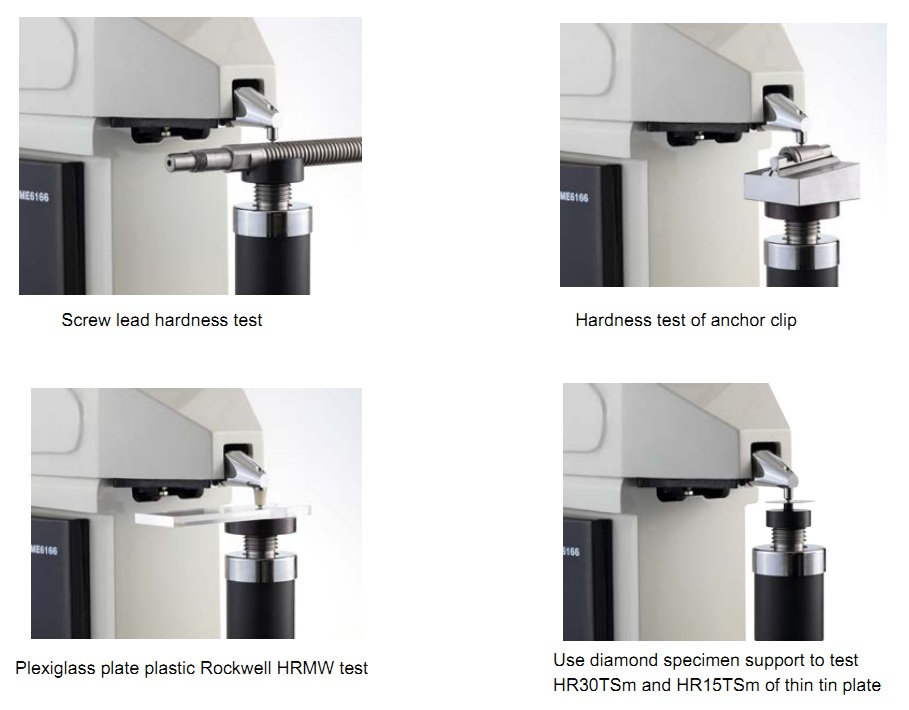

There are different methods of hardness testing, such as Rockwell, Brinell, Vickers, and Shore. Each method has its own advantages and is suitable for specific materials. For example, the Rockwell method is commonly used for metals, while the Shore method is suitable for softer materials like rubber and plastics. Understand the properties of your material and choose a hardness tester that aligns with the appropriate testing method.

2. Consider the Material:

Different hardness testers are designed to test specific materials. Some testers are specifically designed for metals, while others are suitable for non-metallic materials like ceramics or composites. Ensure that the hardness tester you choose is compatible with the material you will be testing.

3. Accuracy and Precision:

The accuracy and precision of a hardness tester are crucial factors to consider. The accuracy refers to how close the measured value is to the true value, while precision refers to the consistency of the results. Look for a hardness tester that provides accurate and repeatable measurements. Check for calibration certificates and ensure that the tester meets the required standards.

4. Load Capacity:

The load capacity of a hardness tester determines its ability to test materials of different hardness levels. It is essential to choose a tester with a load capacity suitable for the materials you will be testing. Consider the maximum and minimum loads the tester can apply and select one that covers the range of hardness values you need to measure.

5. Ease of Use:

Consider the user-friendliness of the hardness tester. Look for features like easy-to-read displays, intuitive controls, and clear instructions. A tester with simple operation and minimal training requirements will save time and effort.

6. Maintenance and Support:

Ensure that the hardness tester you choose is easy to maintain and comes with reliable technical support. Regular maintenance is necessary to keep the tester in optimal condition and ensure accurate results. Look for a manufacturer or supplier who provides prompt customer support, calibration services, and spare parts availability.

Choosing the right hardness tester is crucial for accurate and reliable hardness testing. Consider the testing method, material compatibility, accuracy, load capacity, user-friendliness, and maintenance requirements before making a decision. By following these guidelines, you can select a hardness tester that meets your specific needs and ensures accurate hardness measurements.