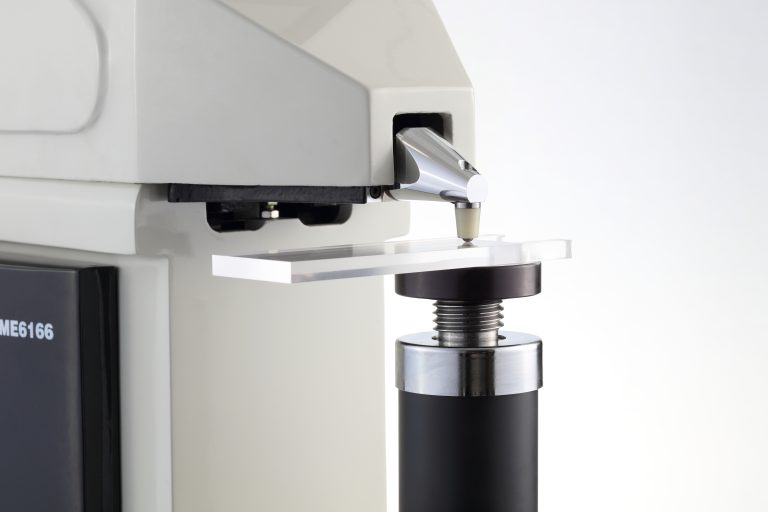

Online Brinell hardness measurement system.

It can be used to measure cast iron, non-ferrous metals, various annealed, quenched and tempered steel materials, and most factory-supplied steel materials.

It is also suitable for testing softer metals such as pure aluminum, copper, lead, tin, zinc, etc. and their alloys. Brinell hardness has high measurement accuracy, good reproducibility and representativeness. It is an indispensable hardness measuring instrument for mechanical metallurgy and metrology departments.

Features of Gantry Online Hardness Tester

The fuselage and workbench adopt precision casting technology, with strong structure, good rigidity, precision, reliability and durability;

1. Portal frame, large movable workbench, maximum moving distance 1000mm;

2. The testing mechanism adopts a high-precision spoke-type pressure sensor; the loading device has a built-in precision pressure sensor. The test force value is accurate, stable and reliable, and has an automatic compensation function for the test force.

3. The self-developed gate-type electronic Brinell hardness tester special numerical control system is adopted, which operates at a fast speed. The test force is applied in a fully closed-loop gradient from fast to slow, ensuring that the test force is applied smoothly and without impact;

4. Adopts contemporary advanced high-speed microprocessors, with fast instant response, ensuring that the test force accuracy is stable within ±1%;

5. Stepper motor, high-precision ball screw and linear guide rail; precise positioning and easy maintenance;

6. Test force, loading saturation time, feed speed, and test speed can be manually adjusted and controlled;

7. The test process is automated and there is no human error;

8. The image processing system can capture indentations, automatically display Brinell hardness values, save test data, and generate and print hardness test reports. Automatic conversion of hardness values can also be performed, and the test data is automatically saved in the database.