BEIJING TIME VISION AI INSTRUMENT LTD.-Automated inspection expert

https://onlinemachinemfr.com/

wechat:0086 152 0162 5204

Email: hardnesstester01@gmail.com

———————————-

versitron hardness tester,roughness tester display,thickness of 7 gauge sheet metal,roughness measurement scale,ultrasonic flaw detector cheap supplier,72dl plus ultrasonic thickness gauge,10 mm gauges,roughness tester company,lee hardness tester chart,hardness gage lowest price factory,second hand ultrasonic flaw detector,ultrasonic flaw detection for technicians,measurement of hardness of water,how surface roughness tester works,x-ray fluorescence coating thickness gauge,feeler gauge how to use,leather thickness gauge chart.

From March 27th to 29th, 2024, the “2024 National Agriculture, Forestry, and Medical Bioelectron Microscopy Application Technology and Academic Exchange Conference” was successfully held at Nanjing Evergrande Hotel.

The conference was organized by the National Key Laboratory of Crop Genetics and Germplasm Innovation and Utilization of Nanjing Agricultural University. It is hosted by the laboratory, co-organized by the Collaborative Innovation Center of the Ministry of Modern Crop Production, co-organized by the Jiangsu Electron Microscopy Society, and hosted by Jiangsu Bodong Detection Technology Co., Ltd.

Electron microscope technology has been widely used in agriculture, forestry, medical biology and other research fields, and has become an indispensable experimental method in basic research work in life sciences. According to reports, the conference is held every two years. Due to the epidemic and other reasons, this series of conferences was restarted after seven years of vacancy this year. The three-day conference brought together nearly 400 domestic experts and scholars, front-line electron microscopy workers and related Representatives from instrument companies attended and discussed the cutting-edge applications and development trends of electron microscopy technology in agriculture, forestry, biomedicine and many other fields. Digital Vickers Hardness Tester TH724/724Z https://onlinemachinemfr.com/product/digital-vickers-hardness-tester-th724-724z/

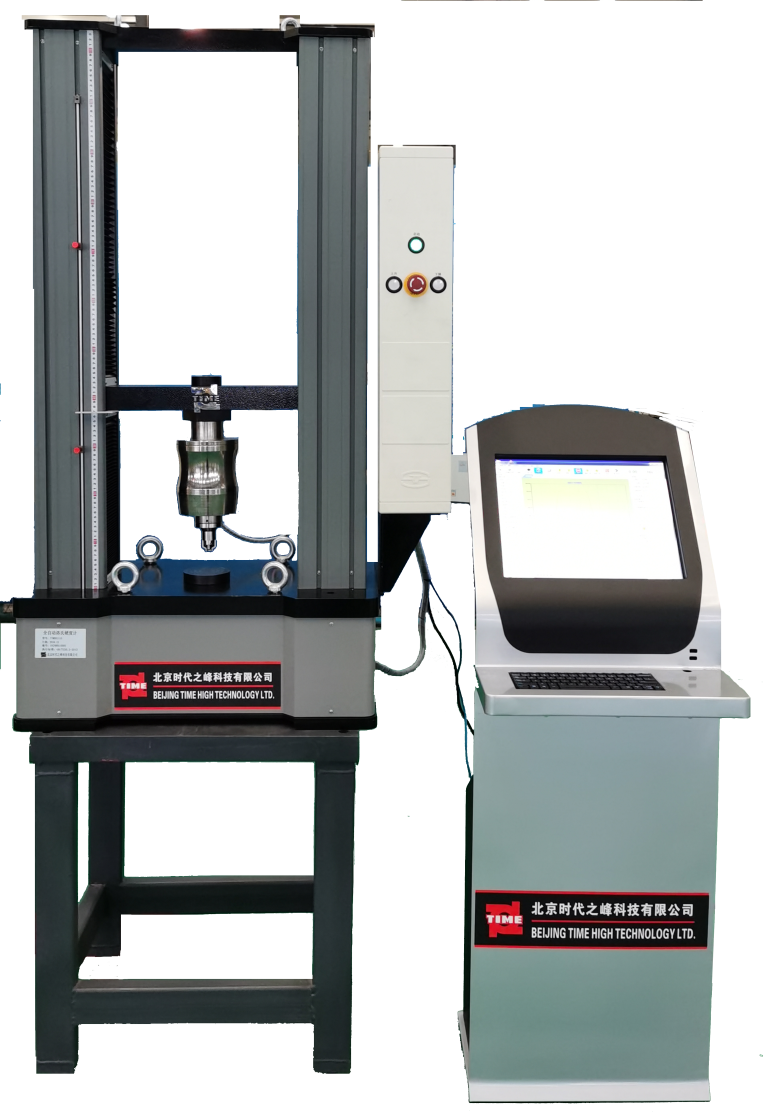

Hardness testing is a common method used to determine the strength and durability of materials in various industries. However, one question that often arises is whether hardness testing is destructive or non-destructive.

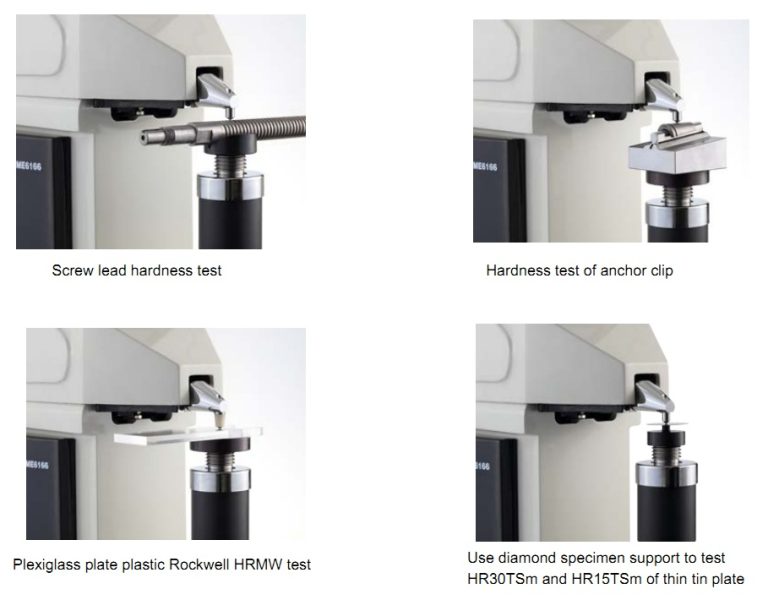

Hardness testing involves applying a specific amount of force to a material’s surface and measuring the depth or size of the indentation left behind. There are different methods of hardness testing, including Rockwell, Brinell, Vickers, and Knoop tests, each with its own advantages and limitations. Fully Automatic Micro Vickers Hardness Tester TIME6610AT https://onlinemachinemfr.com/product/fully-automatic-micro-vickers-hardness-tester-time6610at/

While hardness testing provides valuable information about a material’s mechanical properties, it can be considered destructive to some extent. This is because the process of applying force to the material’s surface can cause damage, such as scratching, denting, or deforming the surface.

In some cases, the damage caused by hardness testing may be minimal and not affect the overall integrity of the material. However, in more sensitive applications where surface quality is critical, the damage caused by hardness testing may be unacceptable.

To address this issue, non-destructive methods of hardness testing have been developed, such as ultrasonic and electromagnetic techniques. These methods allow for the evaluation of a material’s hardness without causing any physical damage to the surface. Computerized Metallurgical Microscope TIME-2000W https://onlinemachinemfr.com/product/computerized-metallurgical-microscope-time-2000w/

While traditional hardness testing methods can be considered destructive to some extent, non-destructive alternatives are available for applications where surface integrity is a concern. It is important for industries to carefully consider the potential impact of hardness testing on their materials and choose the most appropriate testing method based on their specific requirements.