BEIJING TIME VISION AI INSTRUMENT LTD.-Automated inspection expert

https://onlinemachinemfr.com/

wechat:0086 152 0162 5204

Email: hardnesstester01@gmail.com

———————————-

TIME GROUP INC. manufactures NDT instruments, inlcuing Leeb hardness tester, surface roughness tester, coating thickness gauge, ultrasonic thickness gauge, ultrasonic flaw detector, vibration tester and so on. TIME Group Inc. was established in October 1984 by Mr. Peng Weimin and Madam Wang Xiaolan, along with many scientific and technical experts, one of the earliest established modern high-tech manufacturing enterprises in Beijing Zhongguancun area, the pioneer of the mechanical and electrical industry in China as well. What can an Online Portal Brinell Hardness Tester do? https://onlinemachinemfr.com/what-can-an-online-portal-brinell-hardness-tester-do/

Brinell hardness tester is a widely used tool in the field of materials testing. It determines the hardness of a material by measuring the indentation created by a specific load on the material’s surface. This article aims to provide a step-by-step guide on how to use a Brinell hardness tester effectively.

Step 1: Preparing the equipment

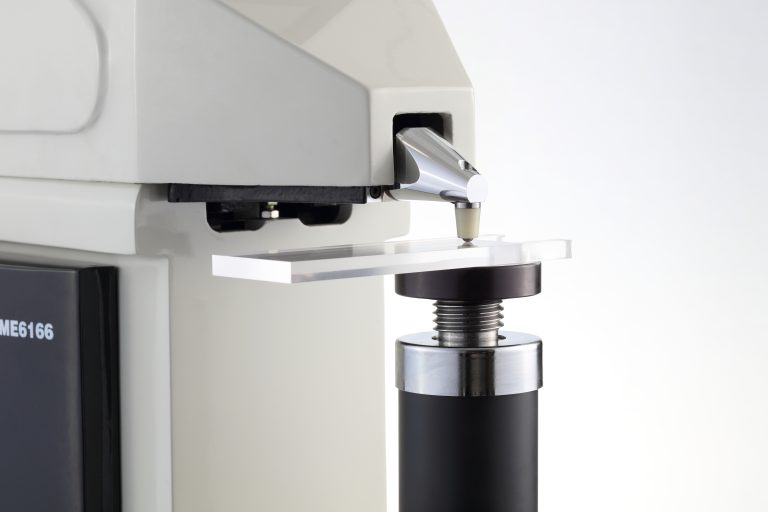

Before using the Brinell hardness tester, ensure that it is calibrated and in proper working condition. Check if the testing machine is clean and free from any debris. Also, make sure that the indenting ball and the test specimen are clean and free from any surface contaminants. Fully automatic Rockwell hardness measuring system. https://onlinemachinemfr.com/fully-automatic-rockwell-hardness-measuring-system/

Step 2: Selecting the load and ball size

Depending on the material being tested, select an appropriate load and ball size. The Brinell hardness test typically uses a load range of 500 to 3000 kgf. The ball size is usually 10mm, 5mm, or 2.5mm in diameter. Refer to the material specifications or standards to determine the suitable load and ball size for accurate results.

Step 3: Placing the test specimen

Position the test specimen on the testing machine’s anvil or support table. Ensure that it is securely held in place to prevent any movement during the testing process. The surface of the specimen should be clean, flat, and free from any irregularities that may affect the accuracy of the test.

Step 4: Applying the load

Adjust the testing machine to apply the selected load on the specimen’s surface. The load should be applied smoothly and without any sudden jerks. The load should be maintained for a specific duration, usually between 10 to 30 seconds, to allow sufficient indentation to form.

Step 5: Measuring the indentation

After the load has been applied and released, measure the diameter of the indentation formed on the specimen’s surface using a calibrated Brinell microscope. Ensure that the microscope is focused correctly to obtain accurate measurements. Repeat the measurement multiple times to ensure consistency. Automatic Dual Digital Display Tension& Compression Testing Machine TLS-S II Series https://onlinemachinemfr.com/product/automatic-dual-digital-display-tension-compression-testing-machine-tls-s-ii-series/

Step 6: Calculating the hardness value

Using the measured diameter of the indentation, the applied load, and the ball size, calculate the Brinell hardness value using the formula provided by the Brinell hardness testing method. This formula relates the hardness value to the applied load and the surface area of the indentation.

Step 7: Recording and reporting the results

Record the obtained hardness value along with the relevant details such as the load, ball size, and testing conditions. Ensure that the results are reported accurately and in compliance with the applicable standards or specifications.

Using a Brinell hardness tester requires careful calibration, selection of appropriate load and ball size, precise measurement of the indentation, and accurate calculation of the hardness value. By following the step-by-step guide outlined in this article, users can effectively utilize the Brinell hardness tester to determine the hardness of various materials.