Mainly realizes direct Brinell or Rockwell hardness testing of large components such as steel gas cylinders, aluminum hydrogen energy gas cylinders, automobile engine cylinder heads, high-speed rail wheel sets, aerospace engine die forging parts (titanium alloy, high-temperature alloy, aluminum alloy), shipbuilding heavy industry forging parts, and oil drill pipes at the production site.

Online Testing Solution for Hydrogen Cylinder Hardness

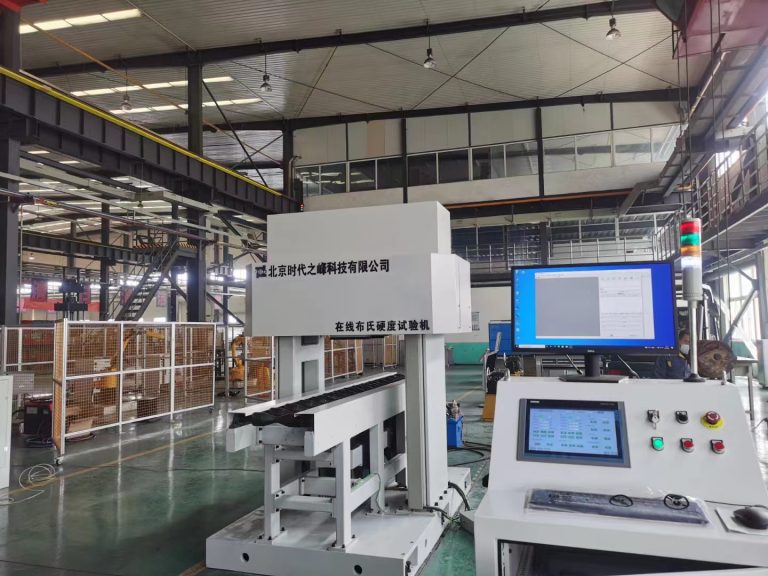

—————-Online Brinell hardness measurement system

Hydrogen cylinders are essential components in various industries, including aerospace, automotive, and energy. The hardness of these cylinders is crucial for ensuring their structural integrity and safety. Traditionally, hardness testing was conducted using manual methods, which were time-consuming and labor-intensive. However, with the advancement of technology, online testing solutions such as the online Brinell hardness measurement system have revolutionized the way hardness testing is performed on hydrogen cylinders.

Online Brinell hardness measurement system:

The online Brinell hardness measurement system is a non-destructive testing method that allows for real-time monitoring of the hardness of hydrogen cylinders. This system consists of a sensor that is placed on the surface of the cylinder, which then measures the hardness using the Brinell hardness test method. The data collected by the sensor is transmitted to a computer system, where it is analyzed and displayed in a user-friendly interface.

Benefits of online testing solution:

One of the main benefits of using an online Brinell hardness measurement system for hydrogen cylinders is the efficiency and accuracy of the testing process. Unlike traditional methods, which require the cylinder to be removed from service for testing, online testing can be performed while the cylinder is in operation. This minimizes downtime and allows for continuous monitoring of the cylinder’s hardness.

Another advantage of online testing solutions is the ability to detect changes in hardness over time. By monitoring the hardness of the cylinder regularly, any deviations from the standard hardness values can be detected early on, allowing for preventive maintenance to be carried out before any safety issues arise.

In conclusion, the online Brinell hardness measurement system is a valuable tool for ensuring the safety and reliability of hydrogen cylinders. By providing real-time hardness measurements and continuous monitoring, this online testing solution offers a more efficient and accurate method of hardness testing compared to traditional manual methods. Implementing online testing solutions for hydrogen cylinders can help industries improve their maintenance practices and ensure the longevity of their equipment.