The metal that people see looks shiny and strong, and is widely used to make machines, weapons, ships, airplanes, etc. In fact, metal also has its shortcomings. Under the repeated action of various external forces, fatigue can occur. Moreover, once fatigue occurs, it will cause very serious consequences because it cannot be recovered. Practice has proved that metal fatigue is a very common phenomenon. According to statistics over more than 150 years, more than 80% of damage to metal components is caused by fatigue. In people’s daily life, metal fatigue also causes harm. The front fork of a bicycle walking on the road suddenly broke, causing the bicycle to roll over and injure people. It is not uncommon for aluminum shovels to break when cooking, shovels to break when digging, and picks to split into two when digging.

Why does metal fatigue produce destructive effects? This is because the internal structure of the metal is not uniform, resulting in unbalanced stress transmission, and some places will become stress concentration areas. At the same time, there are many tiny cracks at the defects inside the metal. Under the continuous action of force, the cracks will become larger and larger, and the part of the material that can transmit the stress will become less and less, until the remaining part can no longer transmit the load, and the metal components will be completely destroyed. As early as more than 100 years ago, people discovered the damage caused by metal fatigue in various aspects. However, due to backward technology, the cause of fatigue damage cannot yet be identified. It was not until the emergence of microscopes and electron microscopes that mankind continued to make new achievements on the road to uncovering the secrets of metal fatigue, and had ingenious ways to deal with this enemy.

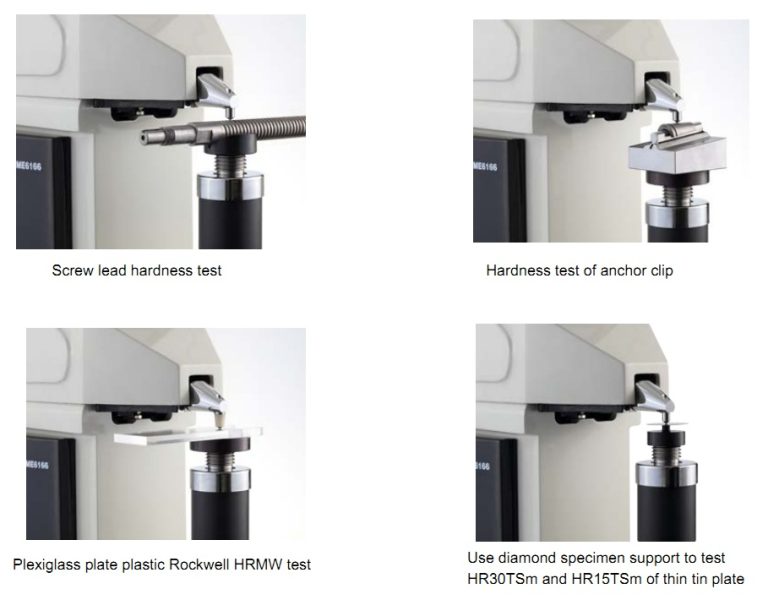

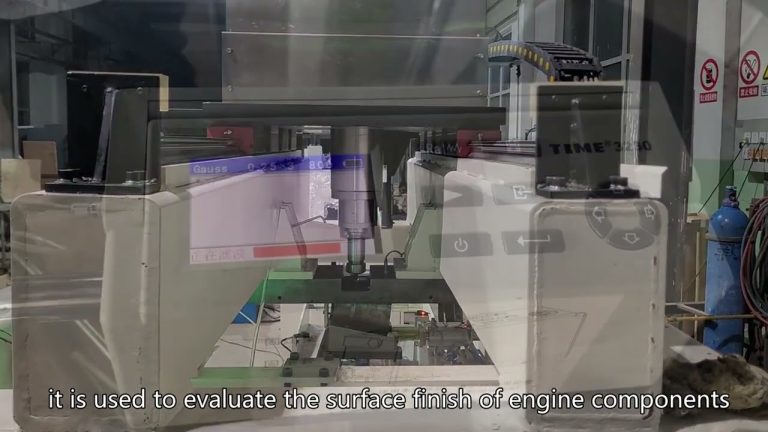

Adding various “vitamins” to metal materials is an effective way to enhance metal fatigue resistance. For example, adding a few parts per ten thousand or a few parts per million of rare earth elements into steel and non-ferrous metals can greatly improve the ability of these metals to resist fatigue and extend their service life. With the development of science and technology, a new technology of “metal immunotherapy” has emerged, which uses previously introduced methods to enhance the fatigue strength of metal to resist fatigue damage. In addition, on metal components, weak links should be minimized, and some auxiliary processes can also be used to increase the surface finish to avoid rust. Anti-vibration measures should be taken for mechanical equipment that generates vibrations to reduce the possibility of metal fatigue. When necessary, testing the internal structure of the metal is also very beneficial to preventing metal fatigue.

Cracks caused by metal fatigue can bring disaster to mankind. However, there are other uses as well. Now, a stress breaking machine manufactured using the fatigue fracture characteristics of metal has been born. It can process metals and non-metals with various properties to produce fatigue fracture in a certain cut. This process only takes 1-2 seconds, and the more difficult the material is to cut, the easier it is to meet people’s needs through this processing.