In the manufacturing industry, the need for accurate and efficient hardness testing is crucial to ensure the quality and reliability of products. One of the most commonly used methods for measuring hardness is the Brinell hardness test, which involves applying a known load to a material and measuring the diameter of the indentation left by the indenter.

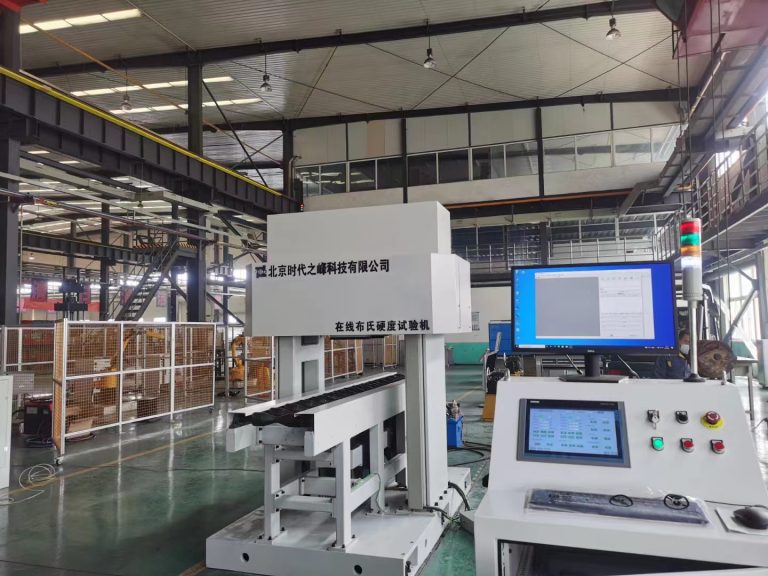

With the advancement of technology, traditional Brinell hardness testers have evolved into fully automatic online hardness testers. These testers are equipped with advanced features such as automated loading and unloading of samples, automatic measurement of indentation sizes, and real-time data analysis and reporting.

The benefits of using a fully automatic Brinell online hardness tester are numerous. First and foremost, it saves time and labor costs by eliminating the need for manual intervention in the testing process. This also reduces the risk of human error, ensuring more accurate and consistent results.

Furthermore, the real-time data analysis capabilities of these testers allow for quick decision-making and process optimization. Manufacturers can easily monitor the hardness of their products throughout the production process and make adjustments as needed to ensure quality control.

Overall, the fully automatic Brinell online hardness tester is a valuable tool for any manufacturing operation looking to improve efficiency and accuracy in hardness testing. Its advanced features and capabilities make it a reliable and cost-effective solution for ensuring the quality and reliability of products.