Metallographic sample cutting machines play a crucial role in the field of materials science and engineering. These specialized tools are designed to prepare metallographic samples for microscopic examination, allowing researchers and engineers to analyze the microstructure of metals and other materials.

Understanding Metallographic Sample Cutting Machines

A metallographic sample cutting machine is an instrument used to cut samples of materials, typically metals or alloys, into smaller pieces for further analysis. The primary goal of this cutting process is to preserve the integrity of the material’s microstructure, ensuring that the samples accurately represent the material being studied.

Key Features

1. Precision Cutting: These machines are engineered to make precise cuts, minimizing damage to the sample. This is essential for obtaining reliable metallographic data.

2. Cooling Systems: During the cutting process, heat can build up, potentially altering the microstructure of the sample. Metallographic cutting machines often include cooling systems, such as water or oil, to dissipate heat and prevent thermal damage.

3. Variety of Blades: Metallographic cutting machines can be equipped with different types of cutting blades, including diamond blades, which are ideal for cutting hard materials. The choice of blade depends on the specific requirements of the sample and the material being analyzed.

4. Automation: Many modern machines offer automated features that enhance precision and efficiency. These may include programmable settings for cutting speed and depth, as well as automated sample positioning.

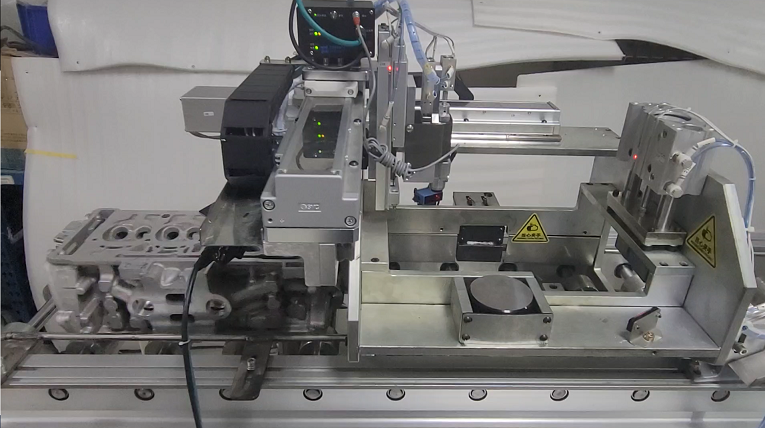

Components of a Metallographic Sample Cutting Machine

– Cutting Table: The surface where the sample is placed for cutting, often adjustable to accommodate different sample sizes.

– Cutting Arm: The mechanism that holds and moves the cutting blade over the sample.

– Cooling System: This system helps to keep the sample cool during the cutting process, ensuring that the microstructure remains intact.

– Control Panel: The user interface that allows operators to set cutting parameters and monitor the cutting process.

Applications of Metallographic Sample Cutting Machines

Metallographic sample cutting machines are widely used in various fields, including:

– Material Research: Researchers use these machines to prepare samples for analysis in laboratories, studying the properties and behaviors of different materials.

– Quality Control: In manufacturing, metallographic sample cutting machines are utilized to inspect materials for defects or inconsistencies, ensuring that they meet industry standards.

– Failure Analysis: Engineers often use these machines to cut samples from failed components to investigate the reasons behind their failure, providing valuable insights for future designs.

Metallographic sample cutting machines are essential tools in the analysis and study of materials. Their precision, advanced features, and ability to preserve the integrity of samples make them invaluable in various applications, from research and development to quality control and failure analysis. As technology continues to advance, these machines will likely become even more sophisticated, further enhancing our understanding of material properties and behaviors.