BEIJING TIME VISION AI INSTRUMENT LTD.-Automated inspection expert

https://onlinemachinemfr.com/

wechat:0086 152 0162 5204

Email: hardnesstester01@gmail.com

———————————-

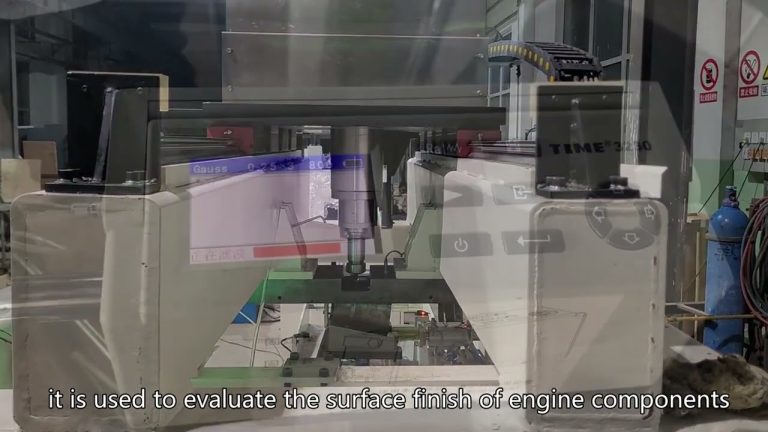

instruments list,gauge thickness in decimal inches,Ultrasonic hardness tester high quality supplier China,thickness gauge 150ml,olympus hardness tester,different hardness testing methods,thickness gauge to mm conversion formula,Ultrasonic hardness tester lowest price factory,talysurf roughness tester,thickness gauge has width equal to,r&d coating thickness gauge,bareiss hardness tester manual,roughness tester with report printing,TIME thickness gauge 950-252,Surface Roughness tester videos. Servo Hydraulic Universal Testing Machine WAW-1000L https://onlinemachinemfr.com/product/servo-hydraulic-universal-testing-machine-waw-1000l/

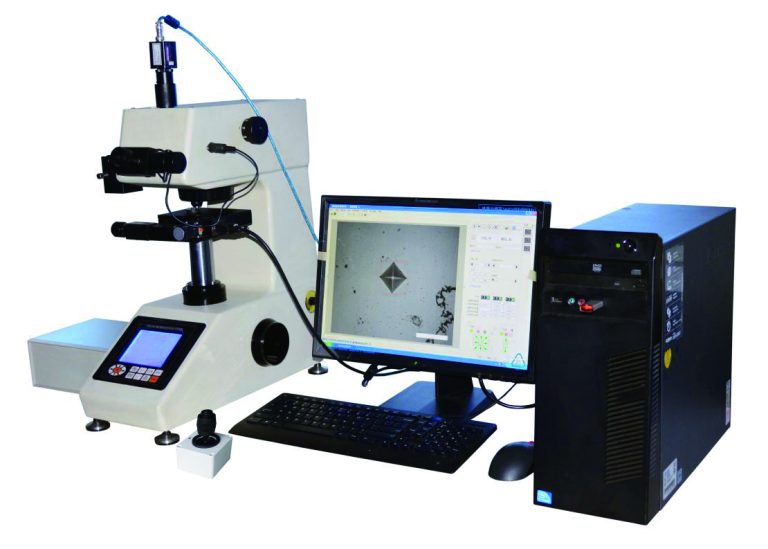

Hardness testers are widely used in materials testing, research and development, failure analysis and prevention, quality control, process optimization and other fields, including automobiles, aerospace, steel, machinery, universities, scientific research, ships, railways, transportation, electronics, energy, and medical , petrochemical and other industries.

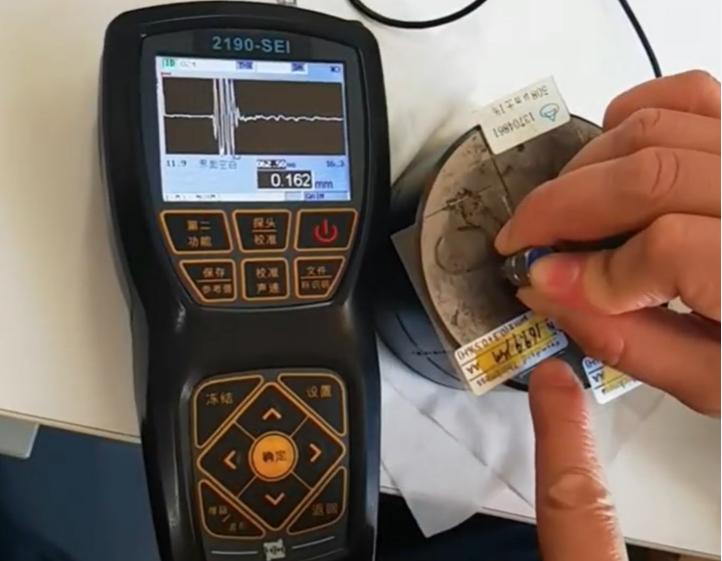

Hardness testing of automotive parts, such as engine pistons, crankshafts, cylinder blocks, brake discs, gears, fasteners, bearings, etc., to ensure the wear resistance, durability and reliability of the parts, thereby improving the overall performance and safety of the car ; Impact Testing Machine JB-500B/JB-W500A https://onlinemachinemfr.com/product/impact-testing-machine-jb-500b-jb-w500a/

Testing the hardness of aero-engine parts, such as turbine blades, turbines, etc., can promptly detect defects and problems within the materials, providing an important basis for engine maintenance and repair;

The energy industry passes hardness testing to promptly discover damage and defects inside equipment to prevent accidents;

The medical industry needs to test the hardness of medical devices and artificial prostheses;

The electronics industry needs to test the hardness of materials to ensure their reliability and durability during use; the petrochemical industry tests the hardness of pipelines to prevent safety issues such as pipeline corrosion and leakage, and so on. Torsion Fatigue Testing Machine PNW-2000 https://onlinemachinemfr.com/product/torsion-fatigue-testing-machine-pnw-2000/

QC

Hardness testers are used for monitoring and quality control during the production process to ensure that products meet quality standards and customer requirements. Through regular hardness testing of products, we can promptly discover material quality problems and prevent the production of substandard products. Hardness testers can also be used for rapid screening and classification during the production process to improve production efficiency and product quality.

Bearing hardness testing

Hardness testing can evaluate the hardness and quality of bearing materials to ensure that the bearings have sufficient wear resistance and durability. And, monitor the hardness changes of the bearing during use, predict its life and reliability, and prevent early failure.

failure analysis

By measuring material hardness and comparing it to standard values, clues to the cause of failure are provided. For example, if a material wears excessively or corrodes, its hardness may decrease. By analyzing hardness changes and the causes of failure, corresponding improvement measures are proposed to reduce the possibility of material failure and improve product quality and reliability.

process control

During the process, the material undergoes various treatments, such as heat treatment, machining, welding, etc., which may affect the hardness of the material. By measuring the material hardness, the impact of the process on the material can be monitored, thereby controlling and optimizing the process and reducing the possibility of failure.

Failure prevention of welded structures:

Detect the hardness of the weld and the range of the heat affected zone, and analyze the mechanical properties of the welded joint. By understanding the hardness distribution of welds and heat-affected zones, the reliability and safety of welded structures can be evaluated to avoid failure of welded structures due to uneven hardness distribution or excessively wide heat-affected zones.