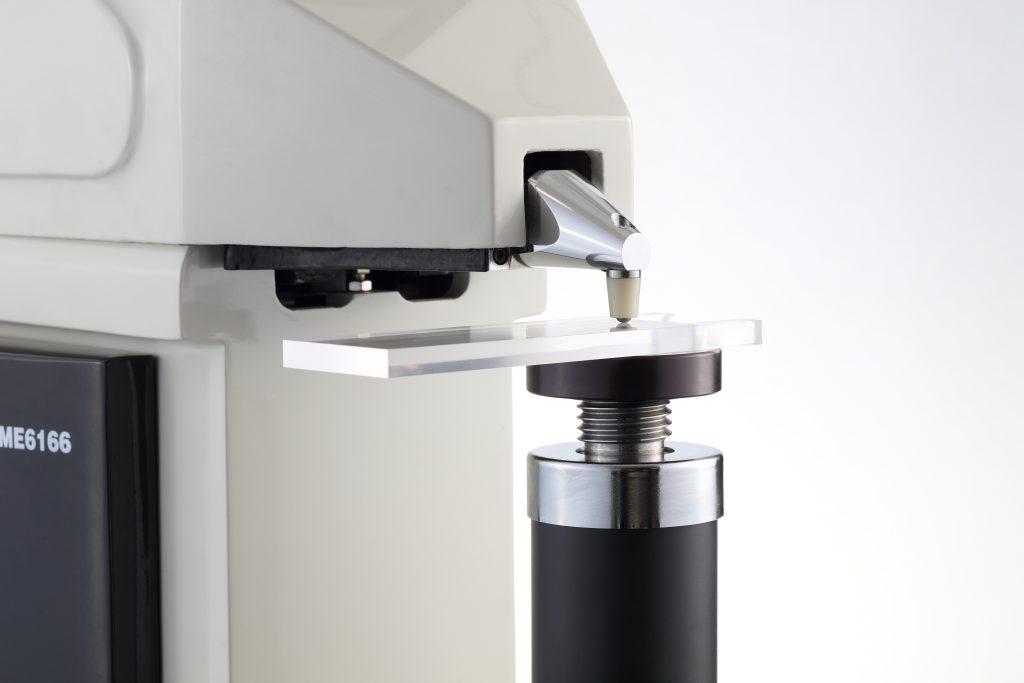

ロックウェル硬度では、頂角120 のダイヤモンドコーンまたは直径 1.588mmの焼入れ鋼球を圧子として使用し、指定された試験力でサンプルの表面に押し込みます。

ロックウェル硬度の値はhの大きさによって決まります。押し込み深さ h が大きくなるほど、硬度は低くなります。逆に硬度は高くなります。

The Rockwell hardness value is determined by the size of h. The greater the indentation depth h, the lower the hardness; conversely, the higher the hardness.

Generally speaking, according to people’s customary concepts, the larger the value, the higher the hardness. Therefore, a constant c minus h is used to represent the hardness. And use every 0.002mm indentation depth as a hardness unit. The hardness value thus obtained is called the Rockwell hardness value and is represented by the symbol HR.

The Rockwell hardness value HR thus obtained is an anonymous number, which is generally read directly from the indicator of the testing machine during the test.

Among the three scales of Rockwell hardness, HRC is the most widely used. Generally, quenched steel or tools are measured using HRC. In the case of medium hardness, the relationship between Rockwell hardness HRC and Brinell hardness HBS is about 1:10.