BEIJING TIME VISION AI INSTRUMENT LTD.-Automated inspection expert

https://onlinemachinemfr.com/

wechat:0086 152 0162 5204

Email: hardnesstester01@gmail.com

———————————-

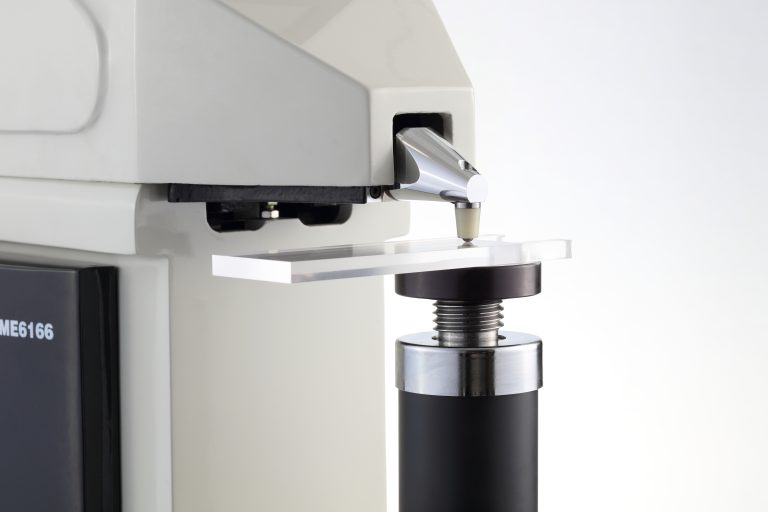

lead hardness tester,thickness gauge zinc coating,rubber thickness gauge,elcometer coating thickness gauge price,mitech ultrasonic flaw detector,Ultrasonic hardness tester good manufacturer Chinese,Ultrasonic hardness tester tutorials ,digital surface roughness tester,diamond hardness tester, Roughness tester measurement surface acceptance criteria,Benchtop hardness tester wholesaler,mic 10 hardness tester manual,hardness test lab report,surface roughness tester digital,rockwell hardness tester video. Digital Rockwell Hardness Tester TIME6102 https://onlinemachinemfr.com/product/digital-rockwell-hardness-tester-time6102/

Failure prevention of composite materials

Composite materials are new materials composed of two or more materials and have excellent mechanical properties and versatility. In the development and application of composite materials, hardness testers are used to evaluate the hardness and related mechanical properties of composite materials, predict their applicability and reliability under different environments and usage conditions, and prevent problems caused by material mismatch or unstable performance. failure problem.

Materials research and development

By comparing the hardness values of different materials, the performance of the materials can be evaluated and provide a basis for the development of new materials. For example, study the hardness characteristics of new materials, compare the hardness differences of different materials, analyze the relationship between the microstructure and hardness of materials, etc. Hardness testers provide important experimental data and results for these studies. Automatic Leeb Hardness Measurement System TIME5210A https://onlinemachinemfr.com/product/automatic-leeb-hardness-measurement-system-time5210a/

Teaching and research

It is mainly reflected in experimental operations and demonstrations, comparing the hardness of different materials, studying the microstructure of materials, practical applications and case analysis, as well as experimental data processing and analysis. Students can better understand the concept of hardness, testing methods and practical applications, cultivate experimental skills and scientific literacy, and also help improve the quality of teaching and the overall quality of students. Automatic Rockwell Hardness Tester TIMEH1110 https://onlinemachinemfr.com/product/automatic-rockwell-hardness-tester-timeh1110/

Scientific researchers also often use hardness testers to conduct scientific research projects to study the hardness properties of new materials, the relationship between the material’s microstructure and hardness, and promote the development of materials science.

Surface hardness testing

Through surface hardness testing, the wear resistance, durability and fatigue resistance of heat-treated workpieces can be evaluated, providing a basis for subsequent heat treatment process adjustments and improving the quality and performance of heat-treated workpieces.

Heat treatment process control

During the heat treatment process, hardness is an important parameter to measure the changes in the internal structure of the material. Through hardness testing, we can understand the hardening degree and phase change process of the material during the heat treatment process, thereby optimizing the heat treatment process parameters and improving the quality and performance of the heat treatment workpiece.

In short, hardness testing is widely used in various materials, including metals, non-metals, hard plastics, composite materials and new materials. The use of hardness testers to test material properties is of great significance for evaluating material properties, controlling product quality, analyzing effectiveness, optimizing process parameters, education and scientific research, etc.