TIME5631 Intelligent Ultrasonic Hardness Tester

TIME5631 ultrasonic hardness tester is an intelligent ultrasonic hardness tester based on the “Industrial Intelligent Detection IoT Platform” of the Times. The instrument has little destructive effect on the surface of the test piece and can be considered as a non-destructive hardness testing device. At the same time, it has fast detection speed and high accuracy. It can measure the hardness of locally hardened parts in a small space and thin parts, making up for the limitations of desktop hardness testers and is popular in the market.

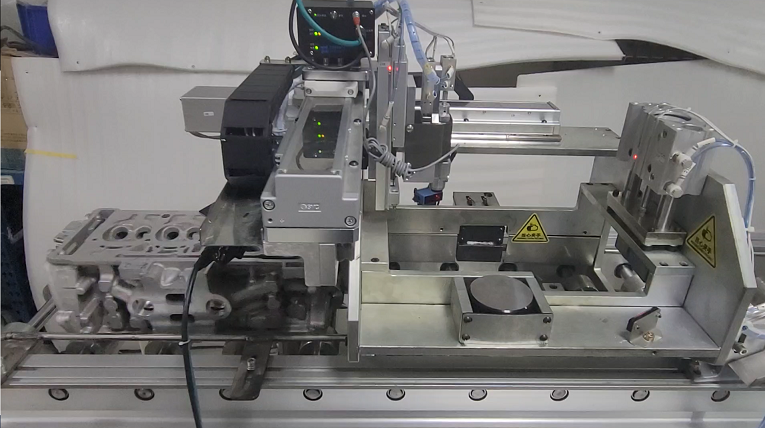

Application occasions: The measurable workpiece parts include belt/plate workpiece measurement, mold hardening layer measurement, blade hardening layer measurement, tooth surface hardening layer measurement, flange edge measurement, wheel, turbine rotor measurement, thin plate measurement, shaft and pipe, container measurement, knife edge position measurement, welding part measurement, etc.

Compliance with standards: The performance indicators of TIME5630 ultrasonic hardness tester meet the requirements of “GB/T34205-2017 Metal Materials Hardness Test Ultrasonic Contact Impedance Method”.

Measurement principle: ultrasonic impedance method.

Product composition: It consists of 1 smart phone + 1 smart ultrasonic hardness tester probe, and the two communicate wirelessly via Bluetooth.

The smartphone realizes the functions of a powerful ultrasonic hardness tester host by virtue of its own software, hardware and network advantages, and can be connected to the Internet of Things platform as an intelligent measurement terminal node.

The design of the intelligent probe is more focused on measurement, and a number of new technologies are introduced in the product design. The positioning method adopts the photoelectric method, abandoning the magnetic sensor positioning method of TIME5630, ensuring that the measurement is not affected by the surrounding magnetic field, and the measurement is more reliable. The guide structure uses an oil-free sliding sleeve to improve the assembly accuracy, avoid the need for manual grinding during assembly, and improve production efficiency.

The intelligent probe is small in size, has no connecting cables, and is easy to carry and operate; the product is powered by No. 5 dry batteries; the software can be upgraded remotely.

The product has applied for an appearance patent.